Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

A Brief Guide To Understanding Spur Gears

The inner workings of machinery are a mystery to many. Due to this reason, people rarely know the importance of gears and the role they play in the effective functioning of sophisticated industrial machinery. There are many types of gear and splines that act as the backbone for many industrial machinery. Spur gear is one of the most commonly used gears in the industrial world. There are many extraordinary features that make this blog sought-after.

A Comprehensive Guide To Understanding Spur Gears

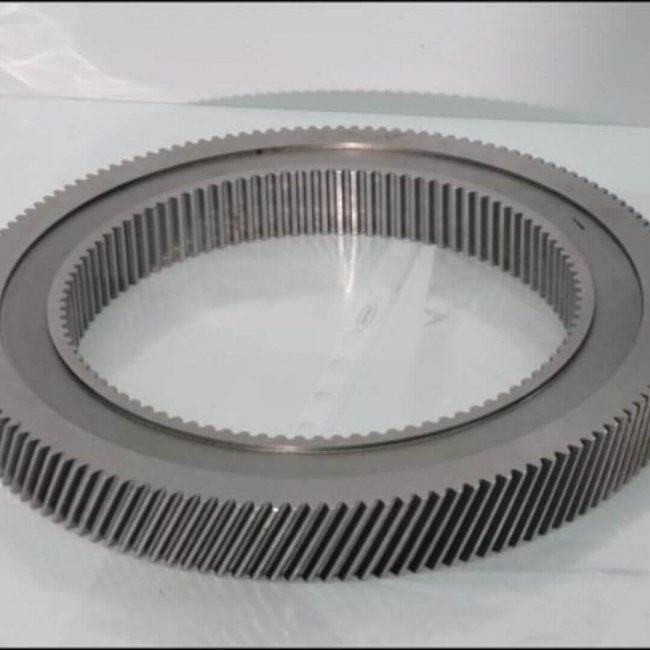

Spur gears boast cylindrical teeth that are parallel to the axis of rotation, making them ideal for transmitting rotational motion and power between two shafts. The simple design combined with effective torque transfer makes them one of the most effective gears when it comes to torque transfer.

Thanks to the simple design, spur gears are also relatively easy to manufacture, making them cost-effective. Their straight teeth allow for efficient power transmission while ensuring that noise and vibration are kept to a minimum.

Gear manufacturers can easily manipulate the size and shape of spur gears depending on the specific application. One interesting fact about spur-type gear is that the number of teeth influences the gear ratio, which in turn affects speed and torque. By adjusting the sizes or adding additional gears in a system, engineers can achieve different gear ratios to suit their needs.

It's crucial to source gears from only dependable gear manufacturers with a proven track record. It's important to note that while spur-type gears excel at transmitting power efficiently, they do have limitations when the quality is not up to the mark. One limitation is that they tend to generate axial thrust forces during operation due to the angled contact between teeth. This can lead to increased wear over time, especially when the gear is manufactured using low-quality materials.

Conclusion

In this comprehensive guide, we have tried to give you an idea about the workings and fundamentals of spur gears. Their simple yet effective design combined with durability and cost-effectiveness make them one of the most popular gear types in different industries. True Gear & Spline Ltd. is one of the leading names when it comes to gear manufacturing in Ontario. With an expansive manufacturing facility equipped with state-of-the-art CNC machinery, we continue to be industry leaders and deliver custom gears with precise tolerances. Get in touch with us today to get a free quote.