Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

A Comparative Analysis of Spline Shafts And Keyed Shafts

Like gears, shafts are widely used across industries to facilitate torque transmission between mechanical components. While there are different types of gears like spur, helical, bevel, and ground, spline and keyed are two common types of shafts. When it comes to choosing between spline shafts and keyed shafts, it happens often that the wrong choice is made, thus affecting the productivity of the process. Both serve the same basic purpose of transmitting torque, but each has its own unique characteristics and advantages that make them suitable for different applications. In this blog post, we'll take a deep dive into the world of spline shafts and keyed shafts and provide you with a comparative analysis

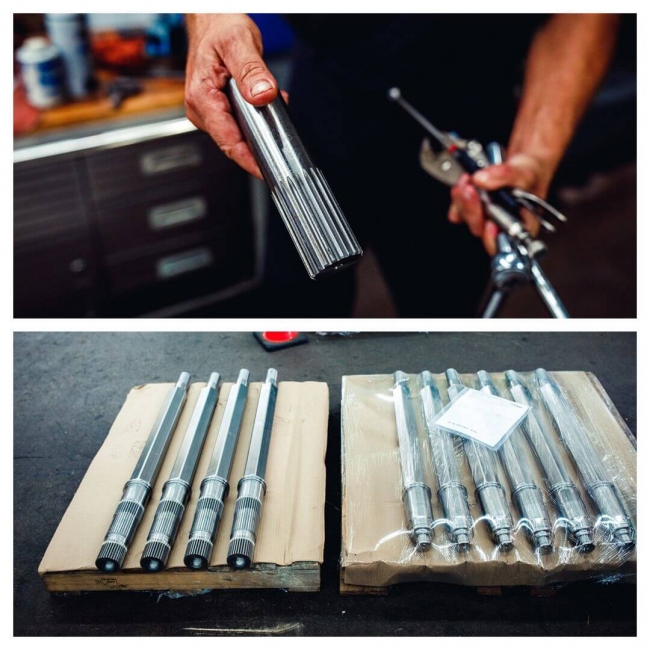

Overview of Spline Shafts

They are essentially a type of mechanical coupling that connects two rotating components to transmit torque. They consist of a series of ridges or teeth (known as splines) on the outer diameter of the shaft, which meshes with corresponding grooves or slots in the inner diameter of another component. One significant advantage of splined shafts is their ability to handle higher torque loads than keyed shafts, thanks to their increased contact area between the splines and mating part. This makes them ideal for applications where heavy-duty power transmission is required. Spline shafts can come in various configurations such as involute, parallel key, serrated and crowned. Different types offer varying degrees of strength, durability and torsional stiffness depending on your specific application requirements.

Overview of Keyed Shafts

As the name suggests, keyed shafts have a keyway machined into them that mates with a corresponding slot on the hub of the mating component. This key and slot arrangement ensures that both components rotate together as one unit. One common application for keyed shafts is in power transmission systems such as machines and gear-and-pulley systems. In these applications, the ability to easily disassemble and service individual components is important, making keyed connections an attractive option. For a keyed connection to work properly, the keyway and slot must be precisely machined to ensure proper alignment and fit.

Conclusion

Spline shafts are better suited for high torque applications due to their larger contact area, which allows for more even distribution of forces. They also provide greater angular flexibility and can handle misalignments well. Keyed shafts are simpler in design and easier to manufacture. They may not be as suitable for high torque applications but they offer excellent accuracy, making them ideal for precision machinery. You can rely on us at True Gear & Spline Ltd. for all your gear and spline needs. We are one of the leading names in custom gear manufacturing. Contact us today to learn about everything we can do for you.