Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

Analyzing The Efficiency of Spur Gear

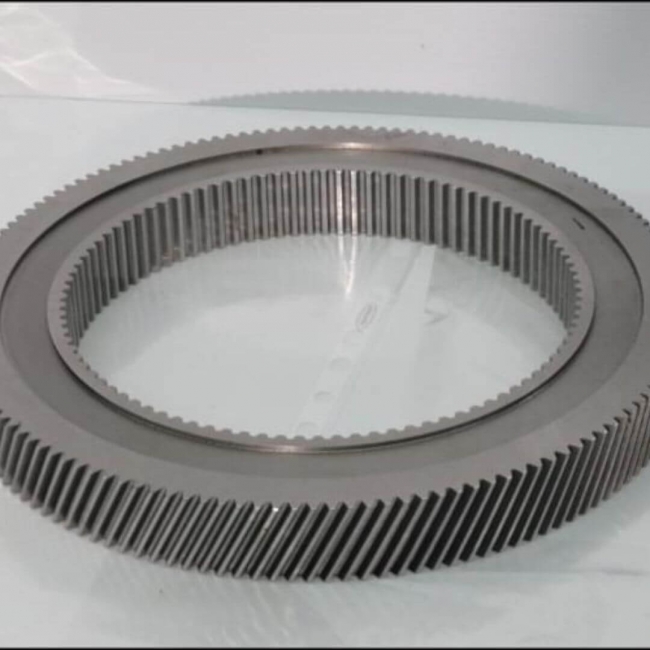

All the advancements made in the industrial and mechanical world in the last many decades wouldn't have been possible without gears. Yes, gears have been silently contributing to the advancements in the industrial world for the last many years. There are different types of gears, namely helical, bevel, ground, and worm gears. However, among all these gears, the spur gear is among the most commonly used. These gears consist of cylindrical teeth that run parallel to the axis of rotation, providing a simple yet effective means of transmitting motion between two shafts. Read this blog until the end to learn what makes spur gears more efficient in transmitting torque.

Understanding What Makes Spur Gears Efficient

One of the most important features that make spur gears so efficient is their straight teeth. The simple teeth design helps gears mesh together seamlessly, thus ensuring maximum contact and significantly reducing slippage.

One of the most common problems faced with other gear types is energy loss during power transmission due to improper meshing and increased slippage. What's more? The simple design of this gear makes it easier for gear manufacturers to mass-produce without compromising quality.

Operating on parallel shafts allows spur gears to facilitate effective load distribution, thus ensuring longevity. Since each tooth bears an equal load, there is less scope for wear and tear, making spur gears highly efficient. The linear motion of spur gears also ensures a direct transfer of rotational force without any lateral forces or sliding friction.

Conclusion

Spur gears have proven to be highly efficient and reliable in various mechanical applications. The simple design combined with even load distribution and linear motion ensures effective torque transmission at all times. True Gear & Spline Ltd. is a leading custom gear manufacturer in Ontario. Our state-of-the-art facility is equipped with the latest CNC machinery, thus ensuring the production of gears and splined shafts with precise tolerances. Contact us today to learn about everything we can do for you.