Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

Merits and Applications of a Bevel Gear

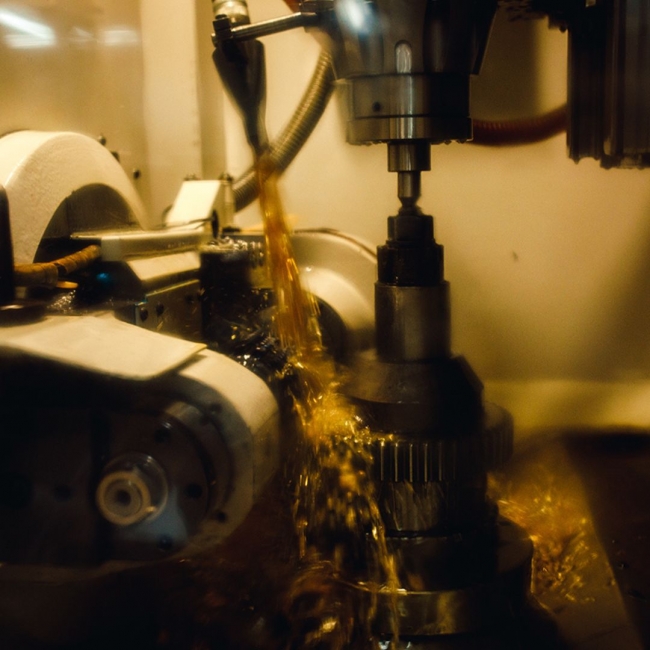

Bevel gears are an essential part of many mechanical systems. Their unique shape allows them to transmit torque between non-parallel shafts with precision and efficiency. But what makes a bevel gear such a popular choice in today's industries? And how can they be applied to real-world situations? In this article, we'll explore the merits and applications of these fascinating components, and show you why they deserve a place in your next project.

Merits of Bevel Gear

There are many advantages to bevel gears, some of which are listed below:

-Bevel gears can handle higher loads and speeds than other types of gears.

-The teeth on these gears are cut at an angle, which allows them to mesh together smoothly and quietly.

-These gears can be used to change the direction of rotation by 90 degrees.

-They can transmit power between shafts that are not parallel to each other.

-These gears are relatively easy to manufacture and are available in a variety of sizes.

-They can be cut in different shapes, such as helical or spiral, to provide smoother operations.

-They can handle higher levels of torque than other types of gear.

Applications of Bevel Gear

The bevel gear is used in a wide range of applications, from small hand-held power tools to heavy-duty industrial machinery. Their unique shape allows them to mesh at right angles, which makes them ideal for transmitting power between two perpendicular shafts. They can also be used to change the direction of rotation or to increase/decrease speed.

One common application for bevel gear is in differential drives. Differential drives are found in many vehicles, including cars, trucks, and tractors. They allow the wheels to rotate at different speeds while still providing equal torque to each wheel. This is necessary when turning corners, as the inner wheels have to travel a shorter distance than the outer wheels.

Another common application for these gears is in gearboxes. Gearboxes are used to change the speed and/or direction of rotation of a shaft. Bevel gears are often used in gearboxes that are located at right angles to the input shaft. This type of configuration is known as a right-angle gearbox.

Right-angle gearboxes are commonly used in industrial applications where space is limited. They are also well suited for applications where high torque is required, such as in conveyor systems and pumps.

Conclusion

Bevel gear technology has been around for a while and its merits are indisputable. The application of bevel gears is vast, with uses ranging from automotive to aerospace. Moreover, these gears have proven to be reliable and efficient in transmitting power between non-parallel axes. You can rely on us at True Gear & Spline Ltd. for all your gear manufacturing needs. We are one of the leading gear manufacturing companies in Ontario. Call us today to learn about everything we can do for you.