Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

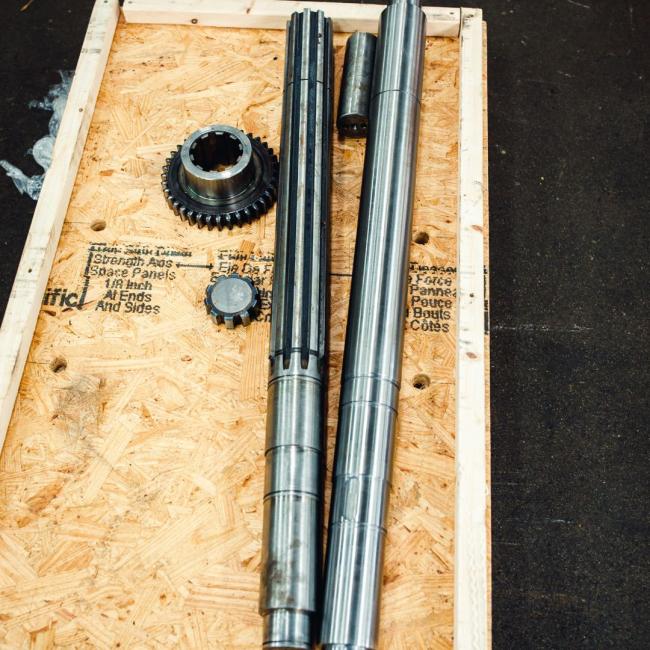

The Anatomy of A Splined Shaft

Splined shafts are on par with gears when it comes to facilitating torque transmission between mechanical components. The anatomy of a gear and a splined shaft are indeed opposites. While gears are often circular in shape spline shafts are long and cylindrical. It is this unique anatomy that makes spline shafts so effective at facilitating uninterrupted torque transfer. True Gear & Spline Ltd. in Cambridge, ON manufactures custom gears and splines. In this blog, we shed light on the anatomy of a spline shaft and how its design makes it effective and dependable. Read this blog until the end to make an informed decision.

Discussing The Anatomy of A Splined Shaft

Spline shafts don't often get the credit they deserve. This seemingly simple yet crucial part plays a significant role in transferring power efficiently within various mechanical systems. A spline shaft is a cylindrical rod with ridges or teeth on it. These ridges often run along the entire length of the shaft. The teeth of splined shafts interlock or mesh with each other to facilitate an uninterrupted torque transmission.

Involute. crowned, parallel, helical, and serrated are some types of splined shafts. Each of these splines is apt for a particular application. It is crucial to talk to a gear expert to understand the perfect fit for your specific applications.

One of the best things about splined shafts is that they facilitate maximum surface contact between each other. What does this mean for torque transmission? Since almost the entire length of shafts feature ridges, they mate with each other facilitating an even load distribution. This prevents the breaking down of shafts and guarantees an uninterrupted torque transmission.

Conclusion

Understanding the anatomy of a splined shaft is crucial for understanding its efficiency. True Gear & Spline Ltd. in Cambridge, ON, is a one-stop destination for all your gear and spline shaft needs. We use CNC machining to guarantee quality, precision, and consistency. Call +1-877-270-9985 to learn about all we can do for you.