Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

The Importance of Precision in Bevel Gear Cutting

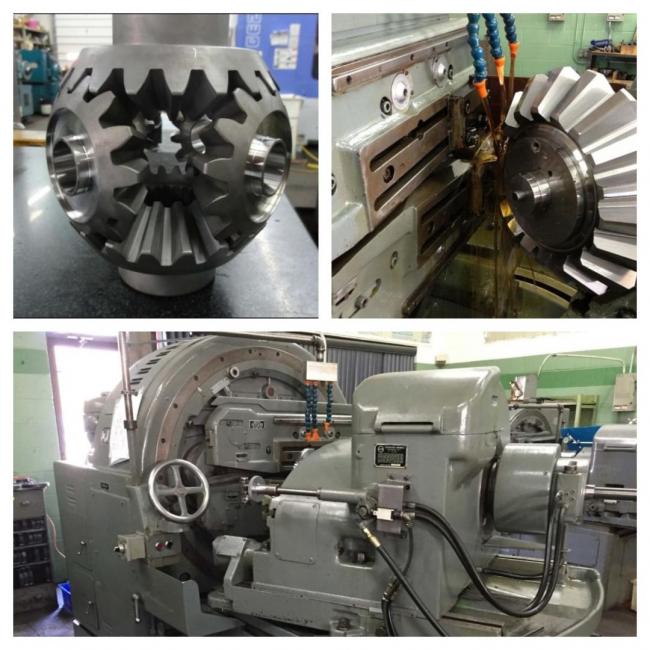

Bevel gears precisely change the direction and speed of intersecting shafts. These conically shaped gears are often used with bevel pinions to alter the perpendicular shaft operations. Bevel-type gear also changes the axis of rotation, making it a crucial part of a vehicle’s differential system, heavy machinery, industrial machinery, and even aeroplanes. True Gear & Spline Ltd., in Cambridge, Ontario, manufactures different gears, including bevel gears. Our state-of-the-art facility is equipped with cutting-edge tools and equipment. In this blog, we shed light on the importance of precision in gear cutting. Also, we discuss the different bevel gear types and their benefits.

Why Is Precision Important In Bevel Cutting?

Precision is the name of the game in the industrial and mechanical world. Even the smallest deviation from the plan can have detrimental effects. Only through sophisticated technology and advanced software can precision be achieved. This is what we do at True Gear & Spline Ltd. Our Gleason Coniflex gear generators are prized jewels that help us achieve perfection. Additionally, our impeccable work holding and gauging facilitate accuracy.

Our Gleason 2A cuts gears up to .25” diameter while the Gleason 24A cuts gears up to 34” diameter. Through years of trial and error, we have put in place foolproof quality check measures. We guarantee custom gear manufacturing without compromising quality or precision.

To reiterate, precision is important in bevel cutting as gear performance depends on it. Deviations from original measurements will halt mechanical operations, causing unnecessary downtimes. Our design and manufacturing team works closely to manufacture custom gears for your needs.

We accurately check mounting distances and verify backlashes, allowing us to recommend changes during design. This ensures no time is wasted manufacturing gears that do not meet your specific requirements. You can trust us for one-off and larger production runs. We guarantee precise tolerance and quick turnaround time.

Different Types of Bevel Gears

Straight Gears

This is the most common bevel type, ideal for low-speed and static loading applications. It gets the name because its teeth are aligned in a straight line. The larger contact area allows straight gears to have impeccable tolerance while mounting. Straight bevel gears are commonly found in differential systems.

Spiral Gears

The curved and oblique teeth set spiral gears apart from their counterparts. Straight gears are prone to vibration because of the instant intersection between the teeth of two gears. The larger gap between spiral gear teeth means the engagement is more gradual and spaced. This leads to less vibration and noise, making spiral gears apt for high-torque applications.

Hypoid Gears

One of the unique things about hypoid gears is that the axes of the meshing gears do not intersect. They are considered a combination of straight and worm gears. However, it is important to note that hypoid gears are way stronger than worm gears. This is because the load is simultaneously conveyed through multiple teeth. The higher power demands the use of special oils and lubricants.

Miter Gears

These gears are manufactured adhering to the ratio of 1:1, meaning the driver and the driven gear have the same number of teeth. Miter gears are mostly used to change the direction of rotation and can have straight or spiral teeth, depending on the intended application.

Benefits of Bevel Gears

Space Efficiency

Bevel gears are increasingly customizable. They can be made compact for applications where space is a challenge. Talk to our experts at True Gear & Spline Ltd. for gears of all sizes. Our gears are reliable and offer unmatched torque transmission.

Versatile

Bevel-type gears can be combined with other gears to reap maximum benefits. The versatility makes these gears highly sought after by many industries.

Torque Control

Torque transmission is crucial for uninterrupted mechanical operations. Bevel gears offer unmatched speed and torque control, making them ideal for different applications. The speed and torque can be controlled by changing the tooth ratio.

High Load Applications

The unique shape and unmatched strength of bevel gears make them perfect for high-load applications. Spiral gears, in particular, offer superior strength due to their gradual engagement with each other.

Conclusion

Look no further than True Gear & Spline Ltd. in Cambridge, Ontario, for all your gear manufacturing needs. We also offer gear hobbing and CNC machining services to clients in Toronto and the GTA. Call 519-653-1301 to get a free quote or learn about all we can do for you. Our bevel gear cutting services are second to none.