Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

Tips for Maintenance and Lubrication of Bevel Gears

Gears make the world go round, literally, Without gears there will be no efficient way to facilitate effective torque transmission, thus bringing the industrial world to a halt. A wide range of industrial machinery is reliant on gears for their effective functioning. The importance of the seamless functioning of gears sheds light on how crucial it is to maintain gears at all times. While there are different types of gears like spur, helical, and ground, we list in this blog tips for the maintenance and lubrication of bevel gears.

Top Tips for Bevel Gear Maintenance

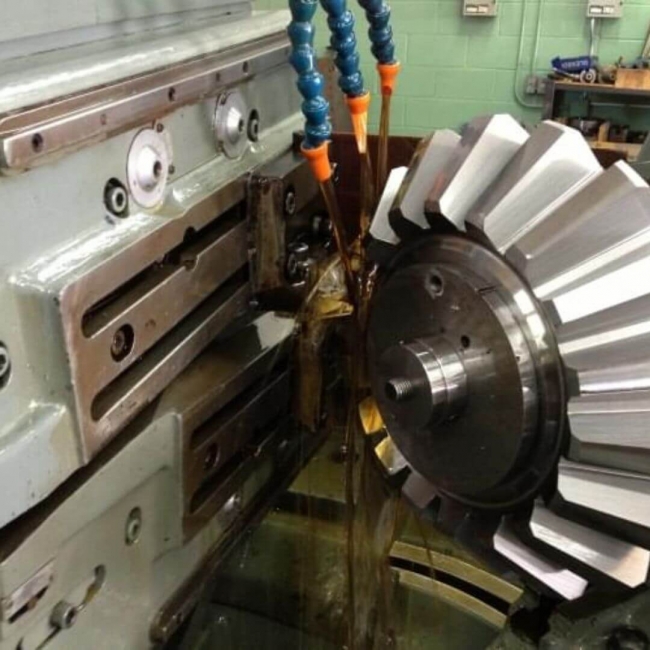

What sets bevel gears apart from the rest of the gears is the fact that the two shafts intersect and gear faces are conically shaped. The complex shape makes it challenging to maintain the gears in top-notch conditions without the right guidance. Neglecting maintenance can lead to wear, damage, and even failure of the gears. We list below a few common tips through which you can maintain gears in good condition.

Proper inspection and cleaning of gears is crucial for their optimal performance. Regularly check for any signs of wear or damage, such as chipped teeth or misalignment. Clean the gears thoroughly using a soft brush to remove dirt, debris, and old lubricant. This helps prevent premature wear and ensures smooth operation. Take the time to inspect and clean your bevel gears to keep them in top shape!

Lubrication is crucial to ensure the smooth functioning of gears. Apply a sufficient amount of lubricant to reduce friction and prevent wear and tear. Use high-quality, oil-based lubricants specifically designed for bevel gears. Check the manufacturer’s manual to check for specific recommendations on the type of lubricant to be used if any. Regularly inspect the lubricant levels and replace or replenish as needed. Proper lubrication will extend the lifespan and efficiency of your bevel gears, keeping them running smoothly for years to come!

Conclusion

Proper maintenance and lubrication of bevel gears are essential for their optimal performance and longevity. With a little bit of attention and planning, gears can be kept in optimal condition for years, thus avoiding the need for expensive maintenance or repairs. However, it is important to understand that no level of maintenance and care can make poorly manufactured gear last long. You can count on True Gear & Spline Ltd. for sourcing industrial-grade gears. Our gear manufacturing capabilities are matched by none. The combination of CNC machining and our expert employees helps us stay ahead of the competition. Consult our gear manufacturing experts for all your gear and splined shaft needs.