Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

Understanding The Anatomy of a Spur Gear

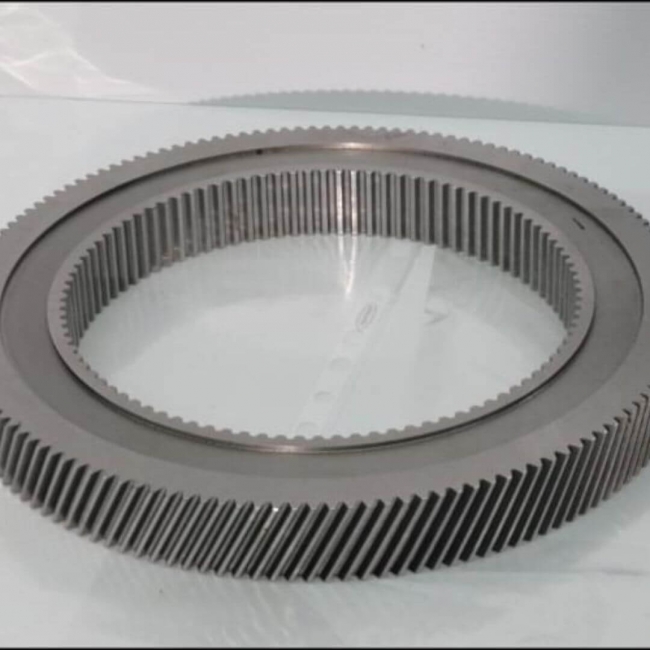

Gears make the world tick, literally! While there are many different types of gears, each with its own set of benefits and applications, we focus in this blog specifically on spur gears. Found in everything from clocks and toy cars to more sophisticated industrial machinery, spur gears are one of the most commonly used gears. Its simple design and effectiveness in torque transfer make it always in demand. Have you ever wondered what is so special about the design of this gear that it facilitates effective torque transfer? If yes. Read this blog until the end.

The Unique Design of Spur Gear Teeth

-

Gear teeth are the key components that transmit power and motion between gears, allowing for smooth and precise operation.

-

The design of gear teeth is carefully engineered to ensure optimal performance. The shape, size, and arrangement of the teeth determine factors such as speed, torque transmission, noise level, and overall durability.

-

One important aspect of spur gear teeth is their profile. They typically have a straight-sided shape with parallel tooth faces. This design allows for the efficient transfer of power along the gear's axis without any radial force or sliding motion.

-

The number of teeth on the gear also affects its performance characteristics. Gears with fewer teeth tend to have higher speeds but lower torque capacity, while gears with more teeth offer increased torque but at slower speeds.

-

The pitch circle diameter plays a vital role in determining the size and spacing of the gear teeth. It ensures proper engagement between meshing gears while maintaining consistent contact throughout the rotation.

Conclusion

Understanding the anatomy of spur gears is crucial for learning how they are able to effectively transfer torque. Gear manufacturing is an intricate and difficult process that requires the latest machinery and skilled workers. Sourcing gear from dependable gear manufacturers guarantees minimal breakdowns and lesser need for expensive repairs. Consult us at True Gear & Spline Ltd. for all your custom gear needs. We use the latest CNC machining technology to deliver gears with tight tolerances to all our clients.