Keep up to date with us on the latest industry news as well as what's going on at True Gear & Spline Ltd. We also post articles for insider tips and tricks, so make sure to check back frequently.

What Are Some Common Applications of Bevel Gears?

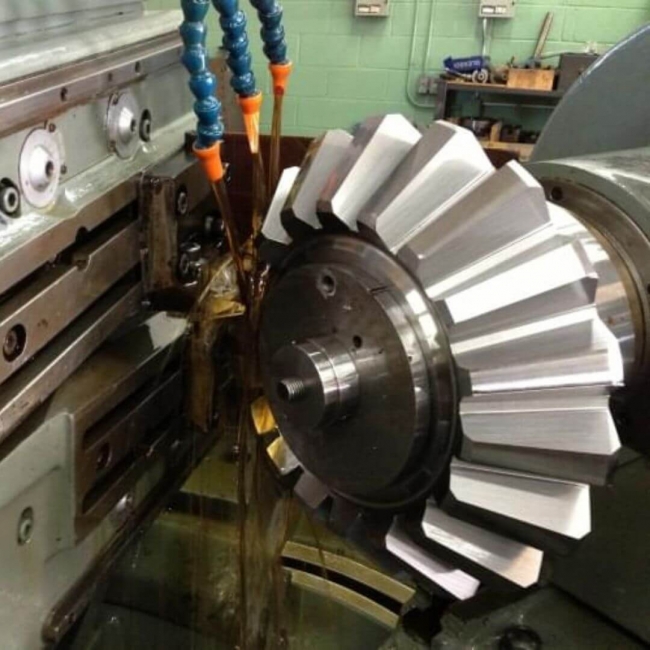

Gears are the hidden powerhouse that makes the industrial world thrive from behind the curtains. Without good-quality gear and splined shafts, efficient torque transmission would be a distant dream. Spur, helical, worm, and ground are some of the most commonly used gears in the industrial world. However, in this blog, we specifically discuss briefly the applications of bevel gear. These gears are unique in the sense that the tooth-bearing faces of the gears are conically shaped. Another unique characteristic of these gears is that they are often mounted on shafts that are 90 degrees apart.

3 Common Applications of Bevel Gears

These versatile gears find applications in numerous industries, contributing to the smooth functioning of machinery and equipment. Here are three common applications of bevel gears:

1. Automotive Industry:

While the automotive industry relies on a wide range of gears, bevel-type gears are found in one of the most important systems of automobiles, the differential system. These gears enable torque distribution between the drive wheels for improved traction and stability during turning maneuvers. They are also used for effectively facilitating power transmission in steering systems, allowing for precise control.

2. Industrial Machinery:

Bevel-type gears can be found in a wide range of industrial machinery such as printing presses, milling machines, and woodworking equipment. These gears facilitate the transfer of rotational motion between intersecting shafts that operate at different angles or directions.

3. Power Tools:

One thing that power tools cannot do without is, you guessed it right, power. The transmission of power and force in these tools is facilitated by these gears. For example, circular saws often incorporate bevel gear sets to transfer power from the motor to the blade at a 90-degree angle for efficient cutting operations.

Conclusion

Bevel gears are versatile mechanical components that find wide application in various industries. Their unique design and functionality make them indispensable in many different systems. From automobiles to industrial machinery, bevel gears play a crucial role in transmitting power and motion between intersecting shafts. True Gear & Spline Ltd. is a leading manufacturer of custom gears including spur, helical, and bevel. Our CNC machining capabilities allow us to manufacture custom gears with tight tolerances.